Empower Your Plant with Custom Machine Vision Software

Measure better. Manage better. Improve your plant's process control, safety, and optimization.

Frustrated with Unreliable Data?

Mineral processing plants are highly complex systems. Without good data, you're left guessing how to control and optimize your processes, risking safety and efficiency. Outdated manual methods result in sparse, unreliable, or non-existent data—making effective management nearly impossible.

We've Been There — And We Can Help

We understand how overwhelming it can be to manage critical systems with unreliable data. With our expertise in machine vision, data science and custom software development, we've helped plants like yours achieve better measurement and process control.

Our Proven Plan to Empower Your Plant

Get in touch

Give us a call, or set up a meeting to discuss your challenges.

Feasibility Study

Let's get a proof of concept to you. What's more, for new clients we do this for free (therefore without a need to onboard us).

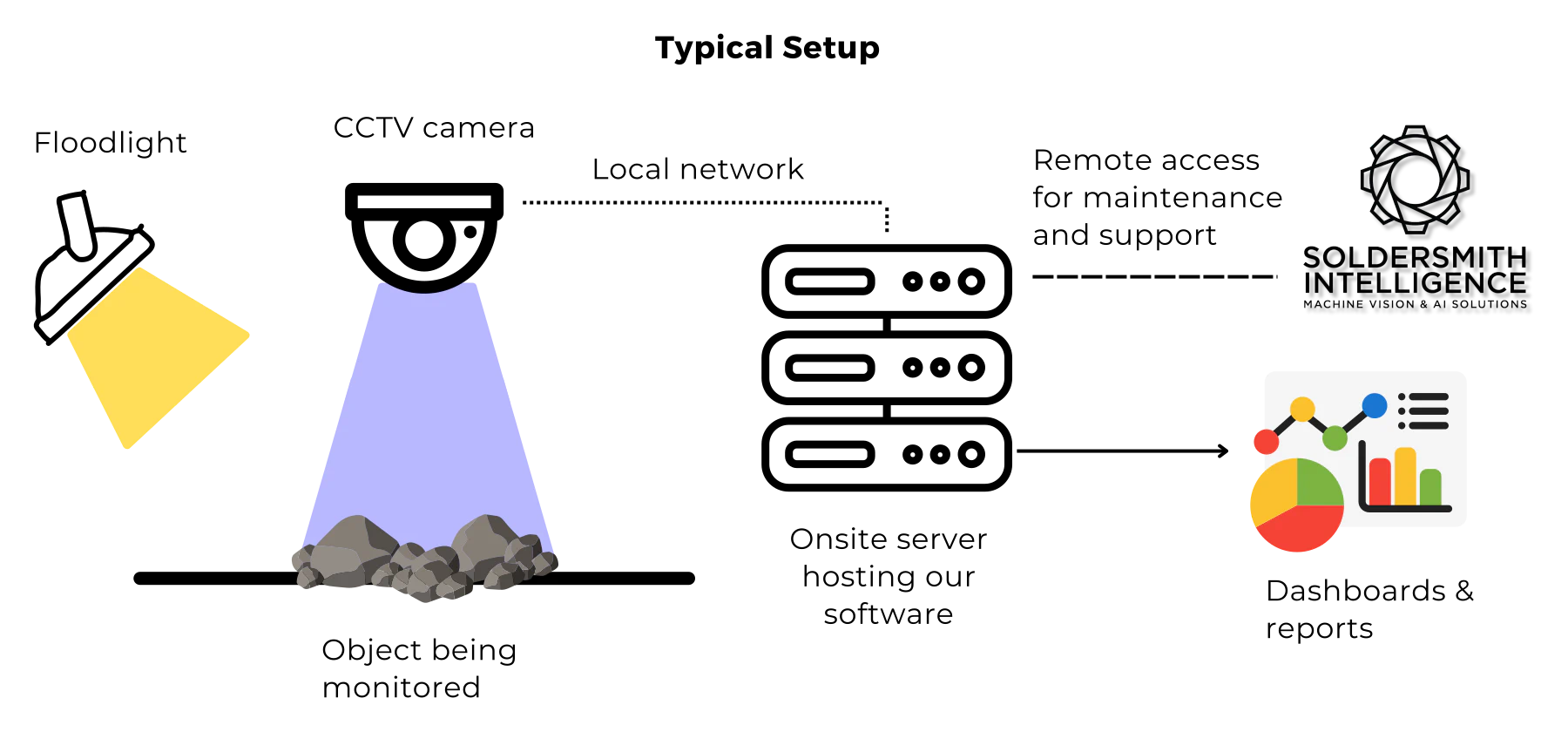

Hardware Setup Etc.

Set up servers and cameras (if not already in place), and other admin.

Trial

We can implement and test our solution. Priced at no-brainer prices.

Monthly SLA

Start a flexible service agreement with no large capital expense. Starting at $1200 per month, plant wide (not per camera).

The Soldersmith Intelligence Advantage

Our approach minimizes risk, maximizing ROI, and carries the benefits of working with an agile, flexible team:

No sales people. No call centers. You speak to the people that develop the software.

We do everything in our power to take the risk on us. We offer free feasibility studies for new clients, low-cost trials to test the system, and monthly SLA with short notice periods.

We don't just provide software, we deliver solutions uniquely tailored to meet your specific challenges and goals.

Leveraging ordinary CCTV cameras, and low monthly cost our technology delivers a high ROI through enhanced efficiency and minimized downtime.

We work with your systems. We are not limited to running in the cloud. Our solutions can also run on your servers, where your data stays in your control.

We've Helped Others, and We Can Help You

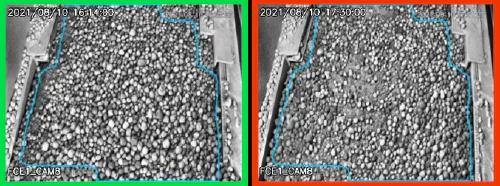

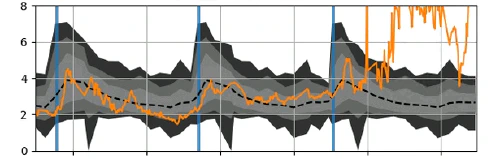

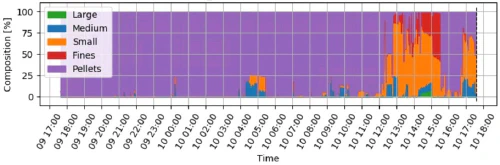

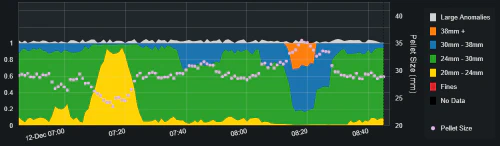

"Working with Soldersmith has been a game-changer for our operation. Their innovative solution uses just a CCTV camera to determine the size of our pellets — an affordable and highly effective approach. Thanks to their system, we're able to track and quantify quality metrics like never before, and our operators have grown so reliant on this technology that they refuse to work without it.

Beyond the product itself, Soldersmith's proactive support is second to none: they promptly notify us of any system issues and are always available to address our requests. We couldn't be happier with the partnership and wholeheartedly recommend Soldersmith for their exceptional service and cutting-edge solutions."

— Anonymous1

Section Head/Metallurgist

"We have had the pleasure of working with Soldersmith on numerous custom projects, and they have consistently exceeded our expectations. Their expertise in machine learning, handling both numerical plant data and visual data, is impressive. They solve complex problems quickly and cost-effectively, starting with high-level analyses to establish feasibility before building comprehensive solutions.

Their resourcefulness, knowledge, and clear communication make them a valuable partner. We highly recommend Soldersmith for their exceptional skills and dedication to delivering top-notch solutions."

— Anonymous2

1, 2 This client considers us a key advantage — so much so that management prefers to keep things discreet.

You Deserve to Feel Confident and In Control

Be empowered with better measurement for improved process control, safety, and optimization.

Or continue risking safety, struggling with poor data, and missing key optimization opportunities.

Frequently Asked Questions

Contact Us

Don't wait until the next crisis, start your journey to better data today.

:

: